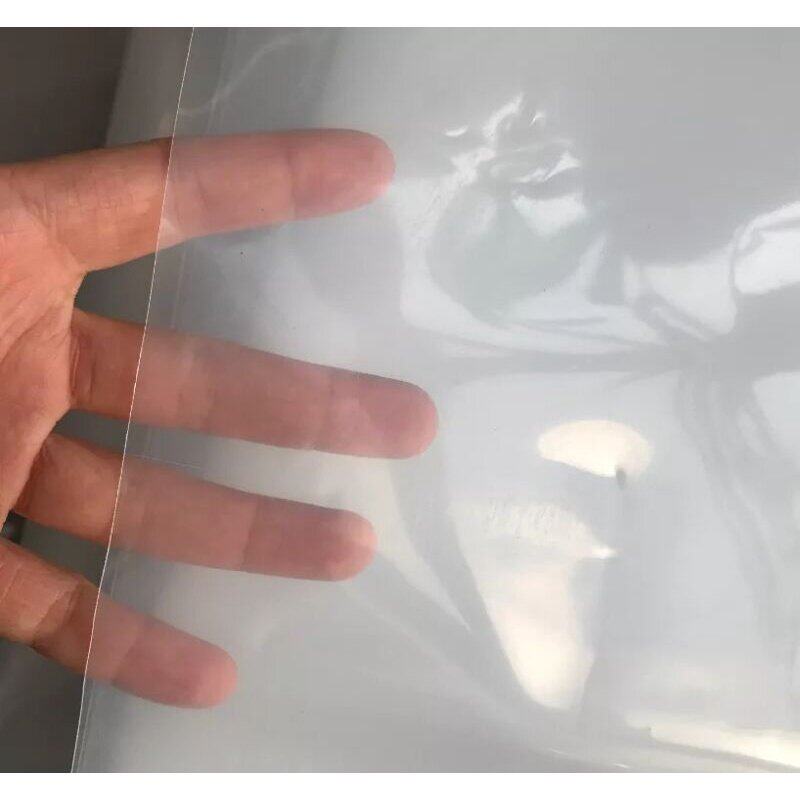

Greenhouse Plastic (Greenhouse Film)

Greenhouse plastic (polyethylene film) is typically produced from high-quality polyethylene materials. This thin plastic layer is installed over a greenhouse’s metal or wooden structure to create an optimal humid and thermal environment for the growth and development of plants.

What Type of Plastic is Used for Greenhouse Covering?

Different types of plastic can be used as greenhouse covers, but the most common and widely used is polyethylene. Polyethylene is a plastic material made from repeating ethylene units.

There are generally two main types of polyethylene used in greenhouse covering:

- Polyethylene Film (Standard Film)

- Supplied in large rolls.

- Commonly used in standard and simple greenhouses.

- Thickness usually ranges between 100 to 220 microns.

- Provides light transmission, thermal insulation, and mechanical strength.

- UV-Stabilized Polyethylene

- Contains additives that improve resistance to UV radiation.

- Prevents the film from degrading under sunlight exposure.

- Extends the lifespan of the greenhouse cover.

Other plastic materials like polycarbonate and PVC (polyvinyl chloride) are also available in the market. These options often offer:

- Higher transparency.

- Better impact resistance.

- Stronger UV protection.

However, they tend to be more expensive and may require special fittings, making them less economical compared to woven polyethylene films.

👉 Overall, polyethylene film remains the most cost-effective solution for greenhouse covering, while alternative plastics are used for specific needs like extra durability, impact resistance, or light clarity.

What is the Ideal Thickness for Greenhouse Plastic?

The required thickness of greenhouse plastic depends on factors such as greenhouse type, climate conditions, plant requirements, and local standards.

In general, greenhouse plastic thickness in the market usually ranges between 100 and 220 microns (0.1–0.22 mm).

The plastic must meet the following requirements:

- Light Transmission: Ensure enough sunlight passes through to support plant growth.

- Thermal Insulation: Retain heat inside the greenhouse and reduce heat loss.

- Mechanical Resistance: Withstand impacts, scratches, and stress caused by weather and farming activities.

- Durability: Maintain long-term performance against changing weather conditions.

👉 Standard greenhouse covers are typically 150–220 microns (0.15–0.22 mm) thick.

- Higher thickness = stronger resistance to tearing, impacts, and weather.

- Too much thickness = reduced light transmission, which may limit plant growth.

Therefore, the right thickness should be chosen based on local climate, crop needs, and manufacturer recommendations.

What Color is Suitable for Greenhouse Plastic?

The most commonly used colors for greenhouse plastic covers are white (or transparent). The main reason is that transparent or white plastic allows sufficient sunlight to enter the greenhouse. Sunlight is essential for photosynthesis, and proper light transmission ensures better growth and performance of plants.

White or transparent covers also help regulate internal temperatures. Since white reflects much of the sunlight, it reduces heat absorption and helps maintain balanced warmth inside the greenhouse.

In some specific cases, colored plastics such as green or blue may be used, especially in regions with very high sunlight and hot climates. Darker shades absorb more sunlight and can filter certain UV rays.

👉 Choosing the right color should always be based on environmental conditions, crop requirements, and manufacturer recommendations.

How Long Does Greenhouse Plastic Last?

The durability of greenhouse plastic depends on factors such as:

- Type of plastic.

- Climate conditions.

- Proper installation and maintenance.

With proper care, greenhouse plastic films can last for several years. However, they are exposed to sunlight, UV radiation, temperature changes, wind, rain, and snow, which may cause discoloration, scratches, tears, or brittleness over time.

Tips to Extend Durability:

- Keep it clean: Regular cleaning prevents dust and deposits from weakening the film.

- Avoid damage: Keep sharp objects away to prevent tears.

- Use UV-stabilized plastic: Increases lifespan.

- Proper installation: A strong greenhouse structure reduces stress on the plastic.

- Protective covers: Use roofing sheets or protective layers to extend durability.

👉 On average, UV-stabilized greenhouse films last 2–5 years, depending on quality and conditions.

What Temperature Should a Greenhouse with Plastic Cover Maintain?

Greenhouse temperature depends on crop type, season, and climate. However, the optimal range for most plants is 18°C to 30°C.

- Spring & Summer: 20°C to 30°C with adequate ventilation or cooling if outside temperatures are high.

- Autumn & Winter: 18°C to 25°C, usually requiring heating systems such as steam heaters, fans, or thermal storage materials.

👉 Exact temperature settings should be based on plant type and growth stage. Ventilation systems also play a key role in regulating day-night temperature variations.

Should Greenhouse Plastic Have UV Protection?

✅ Yes, greenhouse plastic should be UV-stabilized.

UV radiation causes plastic degradation, discoloration, brittleness, and reduced lifespan.

Benefits of UV-Stabilized Plastic:

- Longer durability: Prevents cracks, tears, and discoloration.

- Better light quality: Maintains effective light transmission.

- Plant protection: Shields crops from harmful UV exposure.

👉 Always check manufacturer specifications to ensure the plastic has UV stabilizers included.

How Much Does Greenhouse Plastic Cost?

The price of greenhouse plastic depends on:

- Plastic type.

- Size and dimensions.

- Thickness.

- Additives (UV, IR, EVA, etc.).

- Local market conditions.

Typically sold in large rolls, pricing is calculated per square meter or by weight (kg).

👉 For exact pricing, please contact Tajhiz Gostar SadSotun Engineering Co. for consultation and quotations.

What to Consider When Buying Greenhouse Plastic?

- Type of plastic – Polyethylene, polycarbonate, or PVC.

- Thickness – Typically 100–220 microns, chosen based on climate and crop needs.

- UV protection – Essential for longer lifespan.

- Transparency & light transmission – Ensure sufficient sunlight reaches the crops.

- Mechanical strength – Resistance against tears, scratches, and wind load.

- Ease of installation – Flexible and easy to cut and fix.

- Price vs. quality – Balance cost with durability and performance.

- Reliable supplier – Buy from trusted providers with proven quality.

Common Additives in Greenhouse Plastic

To improve performance, greenhouse plastics may include the following additives:

- UV Stabilizers: Increase resistance to UV radiation.

- Anti-Corrosion Additives: Protect against chemical degradation.

- Anti-Fog: Prevent condensation and improve transparency.

- Anti-Static: Reduce dust accumulation.

- Heat-Resistant Additives: Improve resistance to high temperature changes.

- IR Blockers: Filter excess solar radiation and control heat.

- Anti-Reflective Additives: Reduce glare and increase light penetration.

- Moisture Resistance Additives: Improve resistance against humidity and water absorption.

👉 Additive selection depends on greenhouse location, crop type, and manufacturer design. Consultation with experts, such as Tajhiz Gostar SadSotun technical team, is recommended before finalizing.

TajhizGostarSadSotoun

TajhizGostarSadSotoun